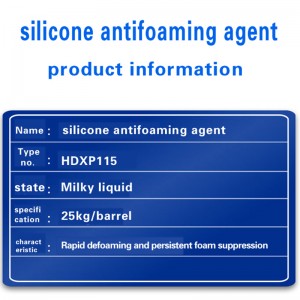

Defoamers,Defoaming Agent

Synonyms in English

Defoamers,Defoaming Agent

chemical characteristics

[Appearance] White viscous emulsion

[PH value] 6-8

[Water dilution] diluted in 0.5%-5.0% foaming solution

Volatile meaning in Chinese

[Stability] No stratification at 3000 RPM /20 minutes

Nonionic type meaning in Chinese

[Temperature resistance] 130℃ no demulsification, no oil bleaching, no stratification

Product introduction and features

Defoaming Agent (English name Defoamers, Defoaming Agent) is a kind of auxiliary Agent, whose function is to eliminate the foam formed by the material in the production process. The main group of organic silicon Defoaming Agent (English name organic silicon Defoamer) is called silicone oil, organic silicon component. Silicone oil is a non-volatile oily liquid at room temperature, insoluble in water, animal and vegetable oil and mineral oil, or very small solubility, both high temperature and low temperature resistance. Inert chemical properties, stable physical properties, no biological activity.

Silicone defoamer is a white viscous emulsion. It has been used in various industrial fields since the 1960s, but large-scale and comprehensive rapid development began in the 1980s. As silicone defoaming agent, its application field is also very wide, more and more attention by all walks of life. In chemical industry, papermaking, paint, food, textile, pharmaceutical and other industrial department of organic silicon defoamer is indispensable in the process of producing a kind of additive, it can not only remove the production process technology bubble on the surface of the dielectric fluid, thus improving filtration, washing, extraction, distillation, evaporation, dehydration, drying process of separation, gasification, such as drainage effect, Ensure the capacity of containers for storing and handling materials

use

Silicone defoamer has a wide range of uses and applications. It is used as defoamer in the fermentation industry, such as erythromycin, linomycin, avermectin, gentamicin, penicillin, oxytetracycline, tetracycline, tylosin, glutamic acid, lysine, citric acid and xanthan gum. It is also used in textile, printing and dyeing, paint, dye, paper making, ink, oil field, sewage treatment and other fields. When used in printing and dyeing, it has good compatibility with additives in dyeing bath, and does not affect the color and color fastness.

It has been reported that silicone is used as antifoaming agent in spray dyeing. In the old dyeing process, dimethylpolysiloxane antifoaming agent is generally used to achieve satisfactory antifoaming agent effect and ensure uniform staining. The new dyeing process, however, uses a high temperature and pressure machine, in which the dye is moved by a spray of dye solution and is stained at the same time. Although the foam produced can be defoaming by ordinary silicone defoaming agent, but under high temperature and high pressure, the general siloxane defoaming agent will produce film precipitation and make the stain produce spots. The application of block copolymers can overcome the above shortcomings, because these antifoaming agent components are soluble in cold water, but not in hot water, so they can act as antifoaming agents. However, the defoaming effect of this copolymer defoaming agent is not satisfactory. If a certain amount of fog-like SiO2 is added to the copolymer, satisfactory defoaming effect can be achieved and uniform dyed fabric can be produced. Used for defoaming polyester fabric in high temperature dyeing process and fermentation process. In addition, can also be used for diethanolamine desulfurization system of defoaming and a variety of oil, cutting fluid, non-freezing liquid, water-based ink system of defoaming, also suitable for printing industry photosensitive resin plate, wash off the uncured resin defoaming, is a very representative, excellent performance, a wide range of uses of silicone defoaming agent

package and transport

B. This product can be used,,25KG,200KG,1000KGBAERRLS。

C. Store sealed in a cool, dry and ventilated place indoors. Containers should be tightly sealed after each use before use.

D. This product should be sealed well during transportation to prevent moisture, strong alkali and acid, rain and other impurities from mixing.