Diamond wire cutting technology is also known as consolidation abrasive cutting technology. It is the use of electroplating or resin bonding method of diamond abrasive consolidated on the surface of steel wire, diamond wire directly acting on the surface of silicon rod or silicon ingot to produce grinding, to achieve the effect of cutting. Diamond wire cutting has the characteristics of fast cutting speed, high cutting accuracy and low material loss.

At present, the single crystal market for diamond wire cutting silicon wafer has been fully accepted, but it has also encountered in the process of promotion, among which velvet white is the most common problem. In view of this, this paper focuses on how to prevent diamond wire cutting monocrystalline silicon wafer velvet white problem.

The cleaning process of diamond wire cutting monocrystalline silicon wafer is to remove the silicon wafer cut by the wire saw machine tool from the resin plate, remove the rubber strip, and clean the silicon wafer. The cleaning equipment is mainly a pre-cleaning machine (degumming machine) and a cleaning machine. The main cleaning process of the pre-cleaning machine is: feeding-spray-spray-ultrasonic cleaning-degumming-clean water rinsing-underfeeding. The main cleaning process of the cleaning machine is: feeding-pure water rinsing-pure water rinsing-alkali washing-alkali washing-pure water rinsing-pure water rinsing-pre-dehydration (slow lifting) -drying-feeding.

The principle of single-crystal velvet making

Monocrystalline silicon wafer is the characteristic of anisotropic corrosion of monocrystalline silicon wafer. The reaction principle is the following chemical reaction equation:

Si + 2NaOH + H2O = Na2SiO3 + 2H2↑

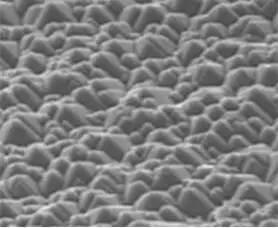

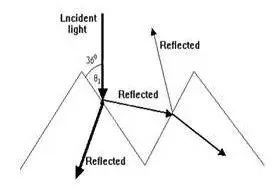

In essence, the suede formation process is: NaOH solution for different corrosion rate of different crystal surface, (100) surface corrosion speed than (111), so (100) to the monocrystalline silicon wafer after anisotropic corrosion, eventually formed on the surface for (111) four-sided cone, namely “pyramid” structure (as shown in figure 1). After the structure is formed, when the light is incident to the pyramid slope at a certain Angle, the light will be reflected to the slope at another Angle, forming a secondary or more absorption, thus reducing the reflectivity on the surface of the silicon wafer, that is, the light trap effect (see Figure 2). The better the size and uniformity of the “pyramid” structure, the more obvious the trap effect, and the lower the surface emitrate of the silicon wafer.

Figure 1: Micromorphology of monocrystalline silicon wafer after alkali production

Figure 2: The light trap principle of the “pyramid” structure

Analysis of single crystal whitening

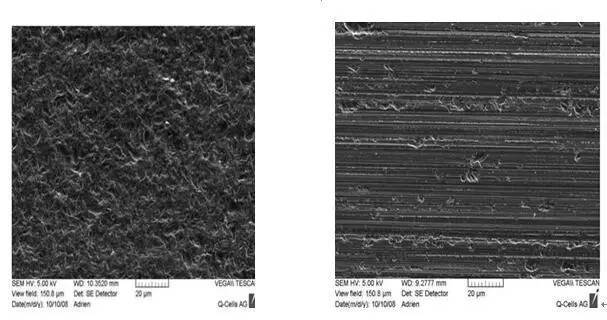

By scanning electron microscope on the white silicon wafer, it was found that the pyramid microstructure of the white wafer in the area was basically not formed, and the surface seemed to have a layer of “waxy” residue, while the pyramid structure of the suede in the white area of the same silicon wafer was formed better (see Figure 3). If there are residues on the surface of monocrystalline silicon wafer, the surface will have residual area “pyramid” structure size and uniformity generation and effect of the normal area is insufficient, resulting in a residual velvet surface reflectivity is higher than the normal area, the area with high reflectivity compared to the normal area in the visual reflected as white. As can be seen from the distribution shape of the white area, it is not regular or regular shape in large area, but only in local areas. It should be that the local pollutants on the surface of the silicon wafer have not been cleaned, or the surface situation of the silicon wafer is caused by secondary pollution.

Figure 3: Comparison of regional microstructure differences in velvet white silicon wafers

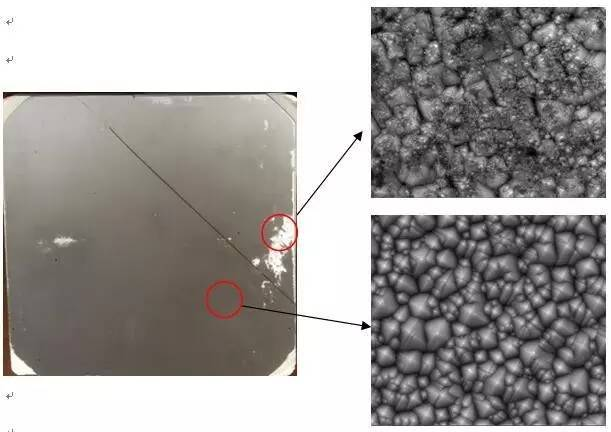

The surface of the diamond wire cutting silicon wafer is more smooth and the damage is smaller (as shown in Figure 4). Compared with the mortar silicon wafer, the reaction speed of the alkali and the diamond wire cutting silicon wafer surface is slower than that of the mortar cutting monocrystalline silicon wafer, so the influence of surface residues on the velvet effect is more obvious.

Figure 4: (A) Surface micrograph of mortar cut silicon wafer (B) surface micrograph of diamond wire cut silicon wafer

The main residual source of diamond wire-cut silicon wafer surface

(1) Coolant: the main components of diamond wire cutting coolant are surfactant, dispersant, defamagent and water and other components. The cutting liquid with excellent performance has good suspension, dispersion and easy cleaning ability. Surfactants usually have better hydrophilic properties, which is easy to clean off in the silicon wafer cleaning process. The continuous stirring and circulation of these additives in the water will produce a large number of foam, resulting in the decrease of the coolant flow, affecting the cooling performance, and the serious foam and even foam overflow problems, which will seriously affect the use. Therefore, the coolant is usually used with the defoaming agent. In order to ensure the defoaming performance, the traditional silicone and polyether are usually poor hydrophilic. The solvent in water is very easy to adsorb and remain on the surface of the silicon wafer in the subsequent cleaning, resulting in the problem of white spot. And is not well compatible with the main components of the coolant, Therefore, it must be made into two components, Main components and defoaming agents were added in water, In the process of use, according to the foam situation, Unable not quantitatively control the use and dosage of antifoam agents, Can easily allow for an overdose of anoaming agents, Leading to an increase in the silicon wafer surface residues, It is also more inconvenient to operate, However, due to the low price of raw materials and defoaming agent raw materials, Therefore, most of the domestic coolant all use this formula system; Another coolant uses a new defoaming agent, Can be well compatible with the main components, No additions, Can effectively and quantitatively control its amount, Can effectively prevent excessive use, The exercises is also very convenient to do, With the proper cleaning process, Its residues can be controlled to very low levels, In Japan and a few domestic manufacturers adopt this formula system, However, due to its high raw material cost, Its price advantage is not obvious.

(2) Glue and resin version: in the later stage of the diamond wire cutting process, The silicon wafer near the incoming end has been cut through in advance, The silicon wafer at the outlet end is not yet cut through, The early cut diamond wire has begun to cut to the rubber layer and resin plate, Since the silicon rod glue and the resin board are both epoxy resin products, Its softening point is basically between 55 and 95℃, If the softening point of the rubber layer or the resin plate is low, it can easily heat up during the cutting process and cause it to become soft and melt, Attached to the steel wire and the silicon wafer surface, Cause the cutting ability of the diamond line decreased, Or the silicon wafers are received and stained with resin, Once attached, it is very difficult to wash off, Such contamination mostly occurs near the edge edge of the silicon wafer.

(3) silicon powder: in the process of diamond wire cutting will produce a lot of silicon powder, with the cutting, mortar coolant powder content will be more and more high, when the powder is large enough, will adhere to the silicon surface, and diamond wire cutting of silicon powder size and size lead to its easier to adsorption on the silicon surface, make it difficult to clean. Therefore, ensure the update and quality of the coolant and reduce the powder content in the coolant.

(4) cleaning agent: the current use of diamond wire cutting manufacturers mostly using mortar cutting at the same time, mostly use mortar cutting prewashing, cleaning process and cleaning agent, etc., single diamond wire cutting technology from the cutting mechanism, form a complete set of line, coolant and mortar cutting have large difference, so the corresponding cleaning process, cleaning agent dosage, formula, etc should be for diamond wire cutting make the corresponding adjustment. Cleaning agent is an important aspect, the original cleaning agent formula surfactant, alkalinity is not suitable for cleaning diamond wire cutting silicon wafer, should be for the surface of diamond wire silicon wafer, the composition and surface residues of targeted cleaning agent, and take with the cleaning process. As mentioned above, the composition of defoaming agent is not needed in mortar cutting.

(5) Water: diamond wire cutting, pre-washing and cleaning overflow water contains impurities, it may be adsorbed to the surface of the silicon wafer.

Reduce the problem of making velvet hair white appear suggestions

(1) To use the coolant with good dispersion, and the coolant is required to use the low-residue defoaming agent to reduce the residue of the coolant components on the surface of the silicon wafer;

(2) Use suitable glue and resin plate to reduce the pollution of silicon wafer;

(3) The coolant is diluted with pure water to ensure that there is no easy residual impurities in the used water;

(4) For the surface of diamond wire cut silicon wafer, use activity and cleaning effect more suitable cleaning agent;

(5) Use the diamond line coolant online recovery system to reduce the content of silicon powder in the cutting process, so as to effectively control the residue of silicon powder on the silicon wafer surface of the wafer. At the same time, it can also increase the improvement of water temperature, flow and time in the pre-washing, to ensure that the silicon powder is washed in time

(6) Once the silicon wafer is placed on the cleaning table, it must be treated immediately, and keep the silicon wafer wet during the whole cleaning process.

(7) The silicon wafer keeps the surface wet in the process of degumming, and can not dry naturally. (8) In the cleaning process of the silicon wafer, the time exposed in the air can be reduced as far as possible to prevent the flower production on the surface of the silicon wafer.

(9) Cleaning staff shall not directly contact the surface of the silicon wafer during the whole cleaning process, and must wear rubber gloves, so as not to produce fingerprint printing.

(10) In reference [2], the battery end uses hydrogen peroxide H2O2 + alkali NaOH cleaning process according to the volume ratio of 1:26 (3%NaOH solution), which can effectively reduce the occurrence of the problem. Its principle is similar to the SC1 cleaning solution (commonly known as liquid 1) of a semiconductor silicon wafer. Its main mechanism: the oxidation film on the silicon wafer surface is formed by the oxidation of H2O2, which is corroded by NaOH, and the oxidation and corrosion occur repeatedly. Therefore, the particles attached to the silicon powder, resin, metal, etc.) also fall into the cleaning liquid with the corrosion layer; due to the oxidation of H2O2, the organic matter on the wafer surface is decomposed into CO2, H2O and removed. This process of cleaning has been silicon wafer manufacturers using this process to process the cleaning of diamond wire cutting monocrystalline silicon wafer, silicon wafer in the domestic and Taiwan and other battery manufacturers batch use of velvet white problem complaints. There are also battery manufacturers have used similar velvet pre-cleaning process, also effectively control the appearance of velvet white. It can be seen that this cleaning process is added in the silicon wafer cleaning process to remove the silicon wafer residue so as to effectively solve the problem of white hair at the battery end.

conclusion

At present, diamond wire cutting has become the main processing technology in the field of single crystal cutting, but in the process of promoting the problem of making velvet white has been troubling silicon wafer and battery manufacturers, leading to battery manufacturers to diamond wire cutting silicon wafer has some resistance. Through the comparison analysis of the white area, it is mainly caused by the residue on the surface of the silicon wafer. In order to better prevent the problem of silicon wafer in the cell, this paper analyzes the possible sources of surface pollution of silicon wafer, as well as the improvement suggestions and measures in production. According to the number, region and shape of white spots, the causes can be analyzed and improved. It is especially recommended to use hydrogen peroxide + alkali cleaning process. The successful experience has proved that it can effectively prevent the problem of diamond wire cutting silicon wafer making velvet whitening, for the reference of the general industry insiders and manufacturers.

Post time: May-30-2024